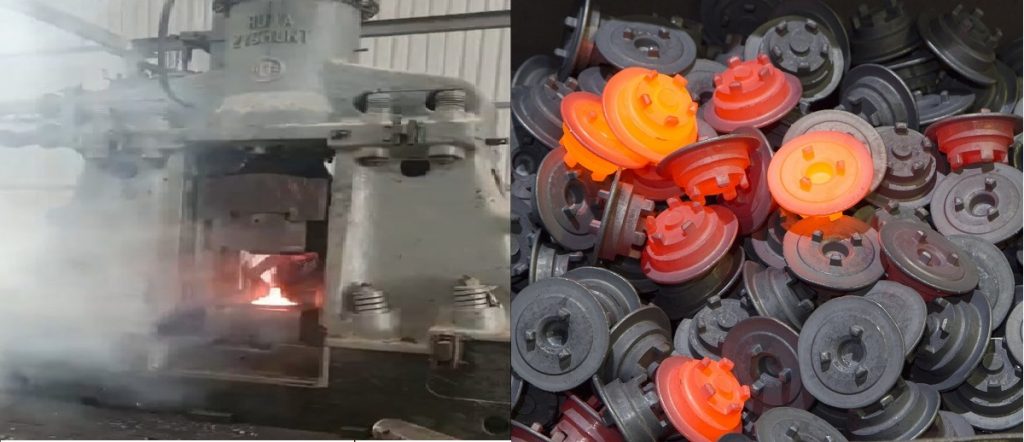

RING AND PINION GEARS

Ring and pinion gears are used to transmit torque and rotate machinery in a variety of applications. They are the primary mechanism by which rotating machinery, such as pumps, fans and motors, function.

Ring and pinion gears are used in almost every machine, from cars to wind turbines to watches. They are incredibly efficient machines that convert energy to motion. The three main types of gears are chain, worm, and ring and pinion.

Each type has its advantages and disadvantages, and sometimes all three are combined in a single machine or device. Imagine a machine that can move a car from one place to another, but instead of using a chain and a motor, it uses gears.

That’s how a machine works. There are two main types of gears: ring gears and pinions. Ring gears are the most common kind of gear. Ring and pinion gears are made of metal and are located at the center of the transmission. The purpose of a transmission is to transfer torque from the engine to the axle. The gears in a transmission rotate when power is applied to them, which causes them to spin.

Rings and pinions are two types of gears that are used in machines and devices. They are located at the center of the shaft or at the center of the base of the shaft.

They are used to turn the shaft to make the machine run. In order to make this work, there are two parts needed: the gear, which are the parts that hold the teeth on each other, and the shaft.