Miniature bevel gears serve to slow down a rotation and allow smooth transitions between rotations. They’re unique in that they turn both clockwise and counter-clockwise (sometimes both at the same time). Their small bevel gears create a powerful frictional force, making them ideal for slowing the motion of a flywheel.

Bevel gears are usually used as an alternative to the sliding gear: the reason is that they are simpler for the application of a torque load and are less likely to lose teeth, and because of their small size they can produce a high torque with a small amount of power, which reduces both noise and backlash. This miniature bevel gears — also known as a spur gear — is available in a variety of versions, including full-face bevel gears, partial-face bevel gears, and internal spur gears.

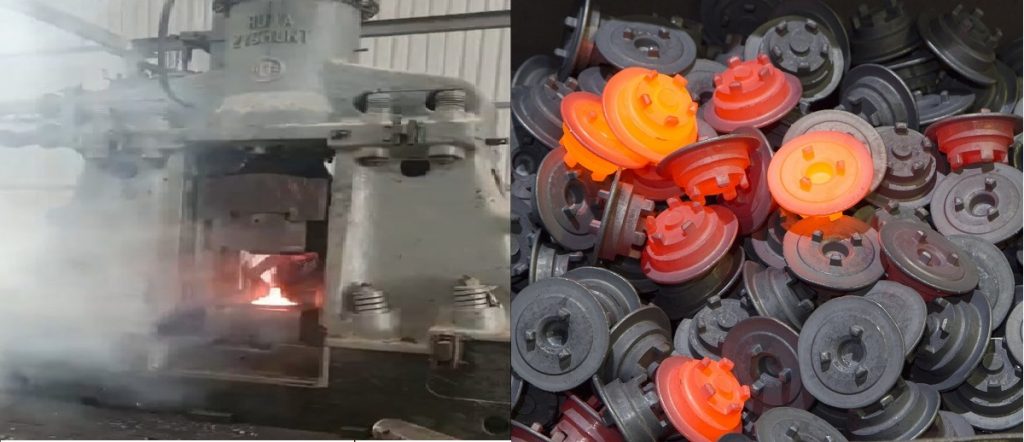

The full-face bevel gear provides the least amount of backlash, but is the most difficult to mount and dismount. The partial- and internal-spur gears provide the easiest mounting and dismounting but have the most backlash. The internal spur gears are considered the most difficult to mount and dismount because of the extra effort needed to set the bevel, but also require the least The miniature bevel gears in this project were made by positioning a pinion and a ring gear of different sizes onto the same shaft. Then, a pinion shaft was mounted in a bearing in the base, and the two were connected by a pinion/ring gear ring for a continuous rotation.

A constant rotation was accomplished by a motor, which was controlled by a microcontroller and controlled using input from the sensors. A stepper motor was used for this project, and the microcontroller controlled its speed. As such, the miniature bevel gears of the Intelligent Science Stations were initially driven by miniature hand-cranked mechanisms that were later replaced by electric motors.

miniature bevel gears or high- (or low-) counters, are gears, often of small, often costly, size, which turn on a central axis, and which are often custom designed or even hand-tooled.

They are used in a variety of applications – sometimes they provide a pathway for the transmission of power; sometimes they simply provide an ornamental finish to an article of manufacture. A miniature bevel gears is smaller than a general-purpose bevel gear, and uses less material, which is a distinct advantage for parts which are to be mass-produced or are otherwise limited,

The high-powered miniature bevel gears motor, as a special class of motors, has a particular advantage when an alternating current (AC) motor is used.

The motor performs an angle-dependent back-EMF force on the shaft which interacts with the bevel gear to produce a force in the rotating direction of the shaft. Hence, a bevel gear motor can act as a servo, something that an alternative DC motor cannot do. This can be very useful in applications such as micromanipulators and camera stabilizers. a small-scale bevel gear is a gear that contains a series of teeth and is driven by a pinion. It is often used where a single wheel is unable to provide enough grip to allow the vehicle to move.