GEARS

Differential gears and pinion their uses can be found almost everywhere. They are used to transfer rotation from one gear to another, which allows for the efficient transmission of power. They are also used to change the direction of rotation of a wheel or a motor. The differential gear is the most common type of differential, which is the main component of a vehicle’s transmission.

Bevel gear manufacturers in a square make a differential gear, which can transmit power to two axles spinning at different speeds, such as in an automobile. They are used in rail transport applications, in marine applications, as automotive components, in liquid storage systems, in power plants and control systems for pumps in printing presses and in a wide variety of other machinery and equipment.

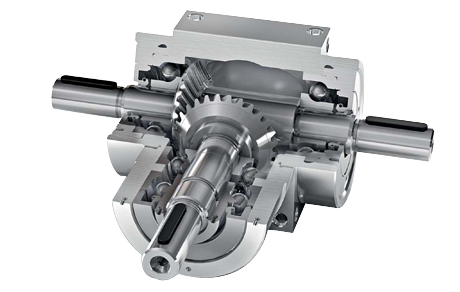

90 Degree Gear. The gearbox used in this vehicle is 90 degree with a difference of 3.2:1, which is the ratio between the input and output shafts. A 90 degree gearbox, called a Hypoid gearbox, is commonly used in rear-wheel drive applications because of its high torque efficiency and low mechanical loss.

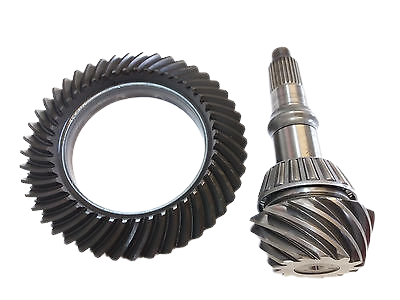

Crown and Pinion gears The pinion is the segment of a gear which rotates around a central axis. The pinion connects the gear to the shaft. The pinion is the most complex part of a gear. It is responsible for turning the gear’s rotation into movement. The gears in your car and the crown on your tooth are both used to measure torque. When you turn the steering wheel, the gears and the crown turn, too. They use the same basic principles to measure torque, and their measurement is called torque.

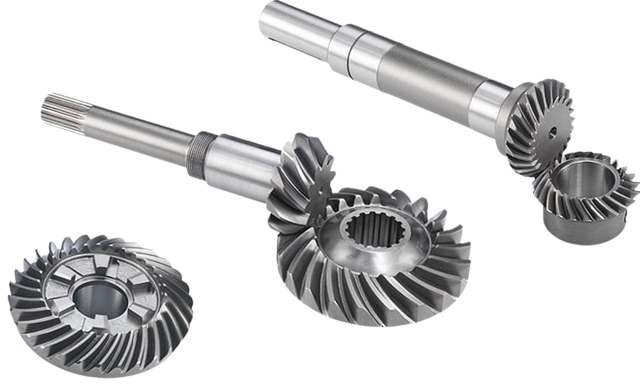

Miniature bevel gears serve to slow down a rotation and allow smooth transitions between rotations. They’re unique in that they turn both clockwise and counter-clockwise (sometimes both at the same time). Their small bevel gears create a powerful frictional force, making them ideal for slowing the motion of a flywheel.

Spiral bevel gear, or bevel gear in general, is a gear in which the teeth are skewed, and not all teeth engage together, to allow the wheel to turn freely. It is a set of gears which are offset from each other, so as to form a ‘deformed’ shape, and is sometimes used to form the teeth of another gear, as when a spur gear is used to form the teeth of a helical gear.

Ring and pinion gears are used to transmit torque and rotate machinery in a variety of applications. They are the primary mechanism by which rotating machinery, such as pumps, fans and motors, function.

Ring and pinion gears are used in almost every machine, from cars to wind turbines to watches. They are incredibly efficient machines that convert energy to motion. The three main types of gears are chain, worm, and ring and pinion.